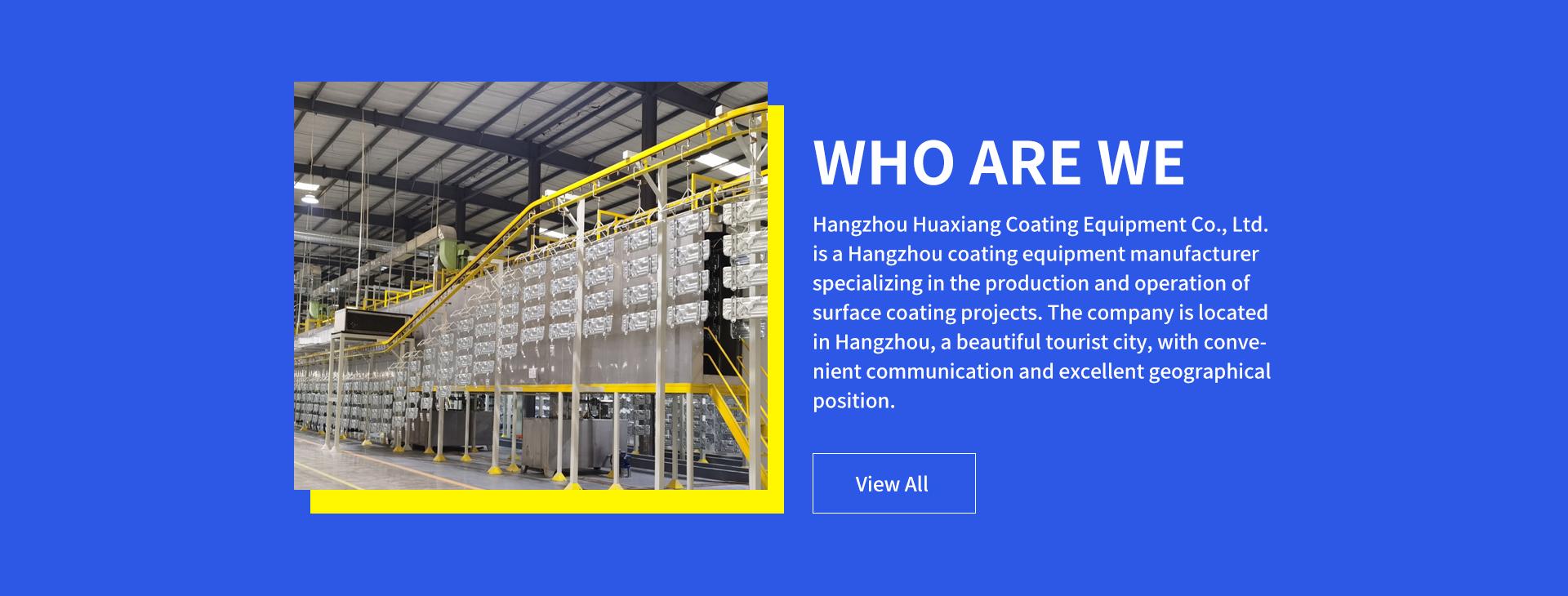

1. Introduction to Powder Coating Conveyor Systems and Structural Components

Powder Coating Conveyor Systems automate the transport of items through coating processes. Key components include conveyor belts, overhead trolleys, chain-driven mechanisms, frames, motors, and control panels. Advanced systems integrate spray booths, curing ovens, and powder recovery units. Their modular design accommodates diverse part sizes, making them ideal for industrial environments.

2. Applications of Powder Coating Conveyor Systems

These systems serve industries like automotive, aerospace, and furniture manufacturing. They coat metal parts such as automotive frames, bicycle components, and appliances. High-volume production lines benefit from consistent finishes and reduced labor costs with powder coating conveyor systems.

3. Pricing of Powder Coating Conveyor Systems

Costs range from 10000to100000+ based on size, automation, and features. Manual systems are affordable, while IoT-enabled automated powder coating conveyor systems justify higher investments for large-scale operations.

4. Proper Usage of Powder Coating Conveyor Systems

Calibrate conveyor speed to align with coating and curing stages. Clean belts regularly to avoid contamination. Secure parts firmly to prevent misalignment during spraying. Adhere to manufacturer guidelines for curing oven temperatures.

5. How to Choose the Right Powder Coating Conveyor System

Evaluate load capacity, throughput speed, and part dimensions. Prioritize corrosion-resistant materials and energy efficiency. Ensure compatibility with existing equipment. Customizable powder coating conveyor systems adapt to niche production needs.

6. Safety Tips for Powder Coating Conveyor Systems

Operators must wear PPE to avoid inhaling powder particles. Install emergency stop buttons and static grounding to prevent fires. Regularly inspect electrical components and conveyor alignment to minimize risks.

7. Efficiency Analysis of Powder Coating Conveyor Systems

These systems reduce waste by recycling excess powder, cutting material costs. Automation lowers labor expenses and ensures uniform output. A well-designed powder coating conveyor system typically delivers ROI within 2–3 years through enhanced productivity.

8. FAQs About Powder Coating Conveyor Systems

Q: What maintenance extends conveyor system lifespan?

A: Monthly chain lubrication and quarterly motor inspections.

Q: Can these systems support heavy parts?

A: Heavy-duty powder coating conveyor systems handle up to 500 lbs.

Q: Are they environmentally friendly?

A: Closed-loop designs reduce waste and emissions.

Q: How to resolve conveyor jams?

A: Clear debris and adjust belt tension.

Q: What automation features are available?

A: PLC controls enable speed optimization and error alerts.

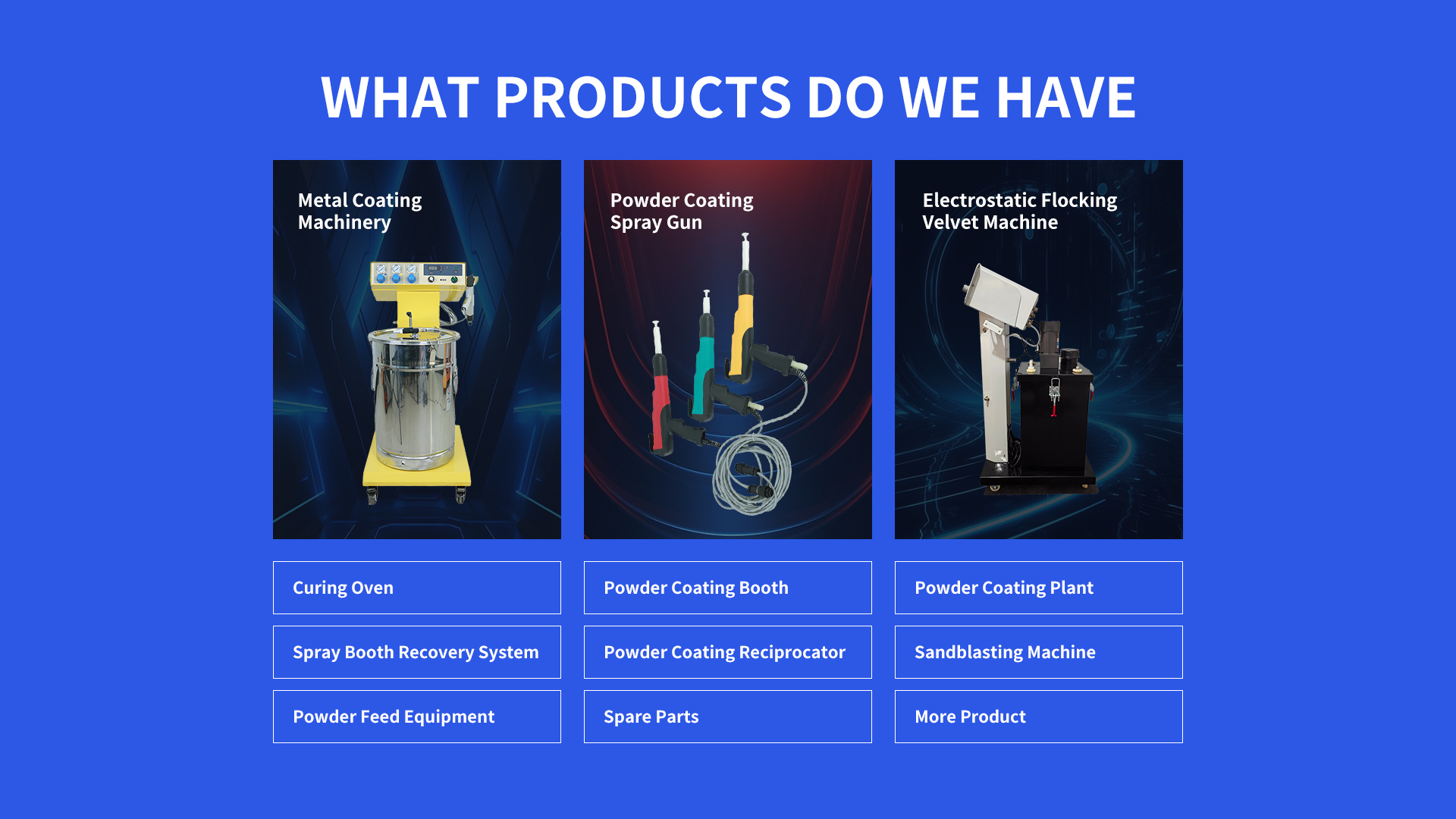

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com